In the world of luxury e-commerce, maintaining impeccable quality is not just an objective; it's an absolute necessity. At ACBUY, we have developed a sophisticated, data-driven approach to quality assurance using a centralized spreadsheet system. This dynamic tool categorizes precise quality standards for every item we handle and leverages performance data to ensure our partners consistently meet our high expectations.

Defining Precise Quality Standards by Category

Our spreadsheet serves as the definitive source for quality benchmarks. Each product category has its own set of meticulously defined tolerances for defects and imperfections. These standards are developed in collaboration with brand experts and authentication specialists.

| Product Category | Product Example | QC Standard Metric | Tolerance Range |

|---|---|---|---|

| Makeup (Lipstick) | ACBUY Dior Lipstick | Color Shade Deviation | ≤ 3% variance from Pantone standard |

| Watches (High-Grade) | ACBUY Rolex Watch | Movement Defect Rate | ≤ 0.5% per batch |

| Leather Goods (Handbags) | ACBUY Hermès Bag | Stitching Irregularity | Zero tolerance for skipped stitches |

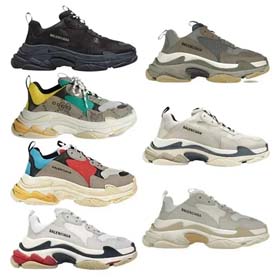

| Sneakers | ACBUY Limited Edition Sneakers | Glue Residue Visibility | ≤ 1mm in non-visible areas only |

Tracking Results & Identifying Trends

Every single item that passes through our authentication centers is logged in the spreadsheet. Each entry records the product details, supplier, inspector, and the results of the multi-point checkpoint. This creates a powerful historical database.

The spreadsheet's primary function is to transform this raw data into actionable intelligence. Built-in formulas and pivot tables automatically calculate defect rates per supplier and per product type, allowing us to move from spotting single issues to identifying systemic problems.

Automated actions

The system is programmed with automatic triggers based on the quality data. If a supplier's performance drops below our strict contractual agreements, the spreadsheet enforces predefined protocols.

Real-World Example:ACBUY Rolex

Continuous Improvement

This isn't just a punitive system; it's a framework for growth. We share granular data with our partners, showing them exactly where their processes are breaking down. This allows for targeted improvements, strengthens our relationships, and ultimately elevates the quality of the entire supply chain, ensuring every customer on ACBUY.club